Introduction to ASTM Flange Dimensions

ASTM flange dimensions play a critical role in industrial piping systems by ensuring compatibility, safety, and pressure integrity. Flanges manufactured as per ASTM material standards and ASME dimensional standards are widely used across oil & gas, chemical, power, water treatment, pharmaceutical, and heavy engineering industries.

Understanding ASTM A105 flange dimensions, ASTM A182 flange dimensions, and ASME B16.5 flange dimensions helps engineers, procurement teams, and fabricators select the correct flange size, pressure class, and material for long-term system reliability.

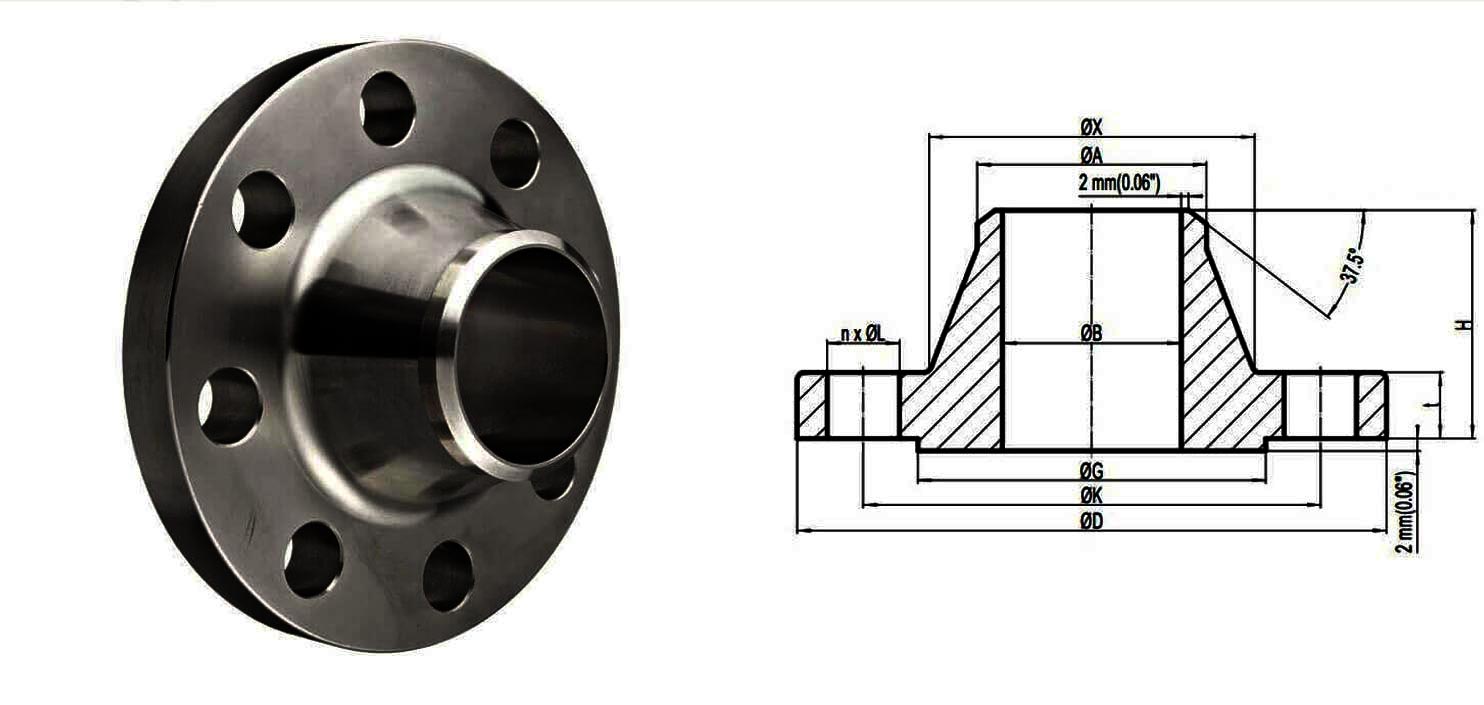

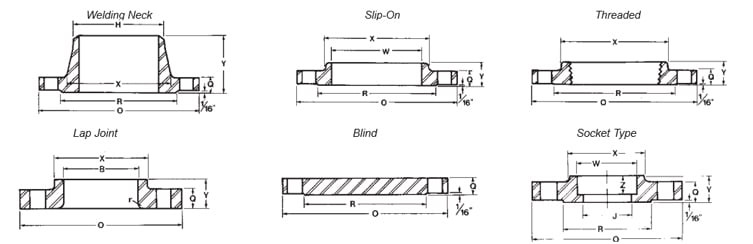

ASTM flange dimensions are standardized measurements used globally to ensure safe, leak-free, and compatible connections in piping systems across industries. These standards cover a wide range of materials and designs, including ASTM A105 flange dimensions for carbon steel applications and ASTM A182 flange dimensions for alloy and stainless steel environments, both manufactured in accordance with ASME B16.5 flange dimensions. Engineers and buyers frequently refer to an ANSI flange dimension chart or a detailed flange size chart to verify outside diameter, bore size, flange thickness chart values, and flange bolt circle diameter before installation. Carbon steel flange dimensions are widely used in oil and gas, power plants, and refineries, while stainless steel flange dimensions are preferred in corrosive, hygienic, and high-temperature applications. Depending on system requirements, different designs such as weld neck flange dimensions for high-pressure pipelines, slip on flange dimensions for low-pressure services, blind flange dimensions for pipeline termination, threaded flange dimensions where welding is not possible, socket weld flange dimensions for small-bore high-pressure lines, and lap joint flange dimensions for systems requiring frequent dismantling are selected. To ensure operational safety, designers also rely on a flange pressure rating chart that defines allowable working pressure based on class ratings, making these standards essential for selecting the correct industrial pipe flange dimensions for long-term performance and compliance.

What Are ASTM Flanges?

ASTM flanges are pipe flanges manufactured using materials specified by ASTM standards such as ASTM A105 (carbon steel) and ASTM A182 (alloy & stainless steel). While ASTM defines the material, the dimensions are governed by ASME / ANSI B16.5 for sizes up to 24 inches.

ASTM Flange Material Standards

ASTM A105 Flange Dimensions

ASTM A105 flanges are forged carbon steel flanges used primarily for:

- High-pressure piping

- Oil & gas pipelines

- Power plants

- Petrochemical industries

They are suitable for ambient and high-temperature services and comply with ASME B16.5 dimensional standards.

ASTM A182 Flange Dimensions

ASTM A182 covers forged alloy steel and stainless-steel flanges such as:

- F304 / F304L

- F316 / F316L

- F11, F22, F5

These flanges are preferred for:

- Corrosive environments

- High-temperature applications

- Chemical and pharmaceutical plants

Despite material differences, ASTM A182 flange dimensions remain identical to ASTM A105 dimensions when manufactured as per ASME B16.5.

ASME / ANSI B16.5 Flange Dimension Standard

ASME B16.5 is the most widely used flange dimension standard globally. It defines:

- Outside diameter (OD)

- Bolt circle diameter (BCD)

- Number of bolt holes

- Bolt size

- Flange thickness

- Pressure classes

ASME B16.5 applies to:

- NPS ½″ to 24″

- Pressure classes: 150, 300, 600, 900, 1500, 2500

ASTM A105 Flange Dimension Chart (ASME B16.5 – Class 150)

| NPS (Inch) | OD (mm) | Bolt Circle (mm) | No. of Bolts | Bolt Dia (mm) | Thickness (mm) |

| 1/2 | 89 | 60 | 4 | 16 | 11 |

| 1 | 108 | 79 | 4 | 16 | 13 |

| 2 | 152 | 120 | 4 | 19 | 16 |

| 4 | 229 | 190 | 8 | 19 | 24 |

| 6 | 279 | 241 | 8 | 22 | 25 |

| 8 | 343 | 298 | 8 | 22 | 28 |

| 12 | 483 | 432 | 12 | 25 | 30 |

| 24 | 813 | 746 | 20 | 36 | 44 |

ASTM A182 Flange Dimensions (Class 300 – Typical)

| NPS | OD (mm) | BCD (mm) | Bolt Qty | Bolt Size | Thickness |

| 2 | 165 | 127 | 8 | 22 | 24 |

| 4 | 254 | 200 | 8 | 22 | 32 |

| 6 | 318 | 270 | 12 | 25 | 38 |

| 8 | 381 | 330 | 12 | 28 | 41 |

| 10 | 445 | 387 | 16 | 28 | 48 |

| 12 | 521 | 451 | 16 | 32 | 51 |

Types of ASTM Flanges with Dimensions

Weld Neck Flange Dimensions

Weld neck flanges feature a long tapered hub that provides excellent stress distribution. Commonly used in high-pressure and high-temperature systems.

Slip On Flange Dimensions

Slip on flanges slide over the pipe and are welded from both sides. These flanges are economical and suitable for low-pressure applications.

Blind Flange Dimensions

Blind flanges have no bore and are used to terminate or isolate pipelines. They are designed to withstand full system pressure.

Threaded Flange Dimensions

Threaded flanges are used where welding is not possible. Suitable for small-diameter, low-pressure pipelines.

Socket Weld Flange Dimensions

Socket weld flanges are ideal for small bore, high-pressure lines and offer smooth internal flow.

Lap Joint Flange Dimensions

Lap joint flanges are used with stub ends and allow easy dismantling, making them ideal for systems requiring frequent maintenance.

Flange Pressure Rating Chart (ASME B16.5)

| Pressure Class | Typical Applications |

| Class 150 | Low pressure water & utility lines |

| Class 300 | Oil & gas pipelines |

| Class 600 | High pressure steam |

| Class 900 | Refinery applications |

| Class 1500 | Extreme pressure services |

| Class 2500 | Critical high-pressure systems |

Important Flange Dimension Terms

Outside Diameter (OD): Total outer diameter of flange

Bolt Circle Diameter (BCD): Diameter of bolt hole circle

Bolt Hole Diameter: Size of bolt holes

Flange Thickness: Total flange face thickness

Raised Face (RF): Most commonly used flange face type

How to Select the Correct ASTM Flange Dimensions

- Identify pipe nominal size (NPS)

- Determine pressure class

- Select ASTM material grade

- Choose flange type

- Verify dimensions from ASME B16.5 chart

Industrial Applications of ASTM Flanges

ASTM flange dimensions are widely used in:

- Oil and gas pipelines

- Petrochemical plants

- Power generation

- Chemical processing units

- Water treatment plants

- Pharmaceutical manufacturing

- Food and beverage industries

Difference Between ASTM A105 and ASTM A182 Flange Dimensions

There is no dimensional difference between ASTM A105 and ASTM A182 flanges when manufactured as per ASME B16.5. The difference lies only in material composition and performance.

Conclusion

ASTM flange dimensions are standardized to ensure safety, strength, and interchangeability in piping systems. Whether you are sourcing ASTM A105 carbon steel flanges or ASTM A182 stainless steel flanges, understanding ASME B16.5 flange dimensions is essential for correct installation and long-term performance.

This detailed guide provides everything from dimension charts, flange types, pressure classes, and material standards, making it a complete reference for engineers, buyers, and manufacturers.