MS Angle Weight Chart: Complete Guide for 2025

When you’re planning a fabrication project—whether for a factory shed, a staircase frame, or a telecom tower—the one thing you can’t afford to guess is the weight of your steel. That’s where the MS Angle Weight Chart becomes essential.

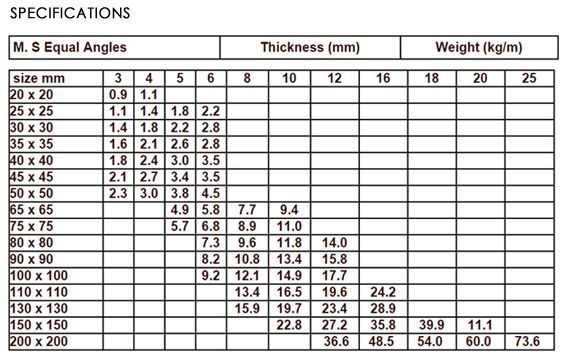

MS Angle Weight Chart is essential for engineers, fabricators, and builders looking to make accurate calculations in steel structure projects. Whether you’re dealing with equal or unequal angles, mild steel (MS) angles are vital components in a variety of construction and fabrication jobs. In this guide, we provide a detailed, human-friendly and updated MS Angle Weight Chart per meter, per foot, and per piece—covering brands like Tata, Jindal, SAIL, and standard grades like IS 2062 and A36.MS Angle Weight Calculation Formula (L-Shaped)

MS Angle Weight kg in per miter

To calculate the weight of an MS angle:

Formula: Where:

- A = Leg 1 (mm)

- B = Leg 2 (mm)

- T = Thickness (mm)

- 0.00785 = Density of MS in g/mm³

Tata and Jindal MS Angle Weight Chart Per Meter

| MS Angle Size (mm) | Tata Weight (kg/m) | Jindal Weight (kg/m) |

|---|---|---|

| 50x50x6 | 3.5 | 3.5 |

| 65x65x8 | 7.7 | 7.7 |

| 75x75x6 | 6.8 | 6.8 |

| 100x100x10 | 11.2 | 11.2 |

| 125x125x12 | 16.5 | 16.5 |

Uses of Hot Rolled A36 Steel Angles

- Structural frameworks (residential and commercial)

- Repair and maintenance work

- Construction equipment

- Fabrication of farm implements

- Manufacturing brackets, shelves, and supports

SAIL MS Angle Weight Chart Per Meter

Durgapur Unit

| Dimensions (mm) | Sectional Weight (kg/m) |

| 150x150x12 / 16 | 22.9 / 27.3 |

| 100x100x10 / 12 | 14.9 / 17.7 |

| 130x130x10 / 12 | 19.7 / 23.5 |

| 110x110x10 / 12 | 16.6 / 19.7 |

Bhilai Unit

| Dimensions (mm) | Sectional Weight (kg/m) |

| 70x70x5 / 6 | 5.3 / 6.3 |

| 200x200x24 | 70.8 |

| 50x50x5 / 6 | 3.8 / 4.5 |

| 60x60x5 / 6 / 8 | 4.5 / 5.4 / 7.0 |

| 90x90x6 / 8 / 10 | 8.2 / 10.8 / 13.4 |

| 75x75x5 / 6 / 8 / 10 | 5.7 / 6.8 / 8.9 / 11.0 |

| 150x150x16 / 20 | 35.8 / 44.1 |

Standard Sizes of Equal MS Angle (IS 2062 / A36)

| Leg A (in) | Leg B (in) |

| ½ | ½ |

| ¾ | ¾ |

| 1¼ | 1¼ |

| 2½ | 2½ |

| 4 | 4 |

| 6 | 6 |

| 8 | 8 |

L-shaped MS Slotted Angle (with Pre-punched Holes)

Features:

- Material: Mild Steel

- Design: L-shaped, symmetrical/unsymmetrical

- Customization: Length, hole pitch, size

- Color Options: Zinc-coated, painted

- Applications: Racks, supports, industrial storage

Mild Steel Properties and Mechanical Strength

| Type | Density (kg/m³) | Yield Strength (MPa) | Tensile Strength (MPa) |

| AISI 1018 | 7870 | 370 | 440 |

| AISI 1020 | 7870 | 350 | 420 |

| S275 J0 | 7850 | 275 | 430–580 |

| S355 J0 | 7800 | 355 | 510–680 |

Melting Point: 1350°C – 1530°C

MS Angle Weight Chart – Most Common Sizes

(Per Meter & Per Feet)

| Size (MM) | Kg/m | Kg/ft |

| 40x40x5 | 3.00 | 0.915 |

| 50x50x6 | 4.50 | 1.372 |

| 65x65x8 | 7.70 | 2.346 |

| 75x75x10 | 11.0 | 3.352 |

| 100x100x10 | 14.9 | 4.545 |

| 150x150x20 | 44.1 | 13.441 |

MS Angle Chemical Composition (Avg.)

| Element | % |

| Carbon (C) | 0.23 |

| Silicon (Si) | 0.40 |

| Sulphur (S) | 0.05 |

| Phosphorus (P) | 0.05 |

| Carbon Equivalent (CE) | 0.42 |

This guide not only gives you standard MS angle sizes and weight per meter but also includes brand-specific charts for Tata Steel, Jindal, and SAIL (Steel Authority of India Limited). We also cover:

- Mild steel equal and unequal angles

- Hot-rolled A36 steel angle use cases

- MS L angle per meter & per feet

- Detailed FAQs for buyers and engineers

Let’s dive into the world of steel angles — no jargon, no fluff — just practical, human-understandable content.

What is an MS Angle?

An MS Angle, or Mild Steel Angle, is a structural steel product with an L-shaped cross-section. It comes in equal and unequal sides and is widely used across commercial and residential construction.

Why do professionals use MS Angles?

- Affordable and easy to fabricate

- High load-bearing strength

- Readily weldable

- Widely available across India

Whether you’re building a steel staircase or installing solar panel frames, MS angles are a go-to choice for strength and support.

Internal Links to Related Products

For a complete piping solution, explore our range of stainless steel components:

- Stainless Steel Tube – SS 304/316 Seamless and Welded Tubes

- Heat Exchanger Tubes – ASTM A213, A269, A270 Tubes

- SS Flanges – Class 150 to 2500, WNRF, SO, BLRT

- Sanitary Valves – Butterfly, Ball, Diaphragm Valves

- SS Dairy Fittings – SMS, DIN, IDF, TC Clamp Types

Conclusion

Understanding the MS Angle Weight Chart—whether from SAIL, Tata, or Jindal—gives you the power to estimate loads accurately, budget correctly, and ensure safe structural performance.

From heavy-duty industrial frames to small-scale domestic support structures, MS angles are indispensable. With this guide, you’re equipped with all the essential data you need to make informed buying and design decisions

FAQs

Q1. How do I calculate the weight of an MS Angle manually?

Use the formula: to find the weight per meter. Plug values in mm for accuracy.

Q2. Which brand provides the most accurate MS Angle weights?

Top brands like Tata, Jindal, and SAIL follow BIS standards ensuring minimal variation in weight.

Q3. What grade is best for MS Angle – IS 2062 or A36?

Both are structurally strong. A36 is common in U.S. specs, IS 2062 in India. Choose based on application and compliance.

Q4. What is the standard length of MS Angles?

Usually, they come in 6m or 12m lengths, though customizable options from 10m to 13m exist.

Q5. Where are unequal MS angles used?

They’re ideal for load-bearing corners, shelves, and equipment bases needing asymmetrical support.