sanitary piping fittings Manufacturer

Mahadev Dairy Pharma Fitting Is Leading Manufacturer Of Stainless Steel Sanitary Fittings Use For Pharma Gread Tube & Fitting carries a wide range of sanitary tube fittings at some of the lowest prices online. We offer both 304 and 316L stainless steel alloy in sizing options ranging from 1” up to 12” for select models. Most items are manufactured in accordance with 3A Tube Fitting standards noted on product pages. These items are precision engineered to be utilized in the most demanding environments of the Hi Purity Water System – Process Piping System food, dairy, beverage, and pharmaceutical industries

Sanitary Piping Fittings: Complete Guide to Dimensions, Grades, Prices, and Manufacturers

Sanitary piping fittings are essential in industries where hygiene and product purity are non-negotiable. These fittings form a critical part of process piping systems in sectors like dairy, food and beverage, pharmaceuticals, cosmetics, and biotechnology. Designed with smooth internal surfaces and high-grade stainless steel, sanitary fittings reduce the risk of contamination, support clean-in-place (CIP) and sterilize-in-place (SIP) processes, and comply with global sanitary standards.

In this detailed guide, we’ll explore what sanitary piping fittings are, the standard dimensions they follow, the material grades used in their construction, how their prices vary, and what to look for in a dependable manufacturer.

What Are Sanitary Piping Fittings?

Sanitary piping fittings are stainless steel connectors used in process lines where cleanliness is critical. Unlike general-purpose pipe fittings, sanitary fittings are built with a polished finish and precision geometry to minimize fluid retention and allow easy cleaning. They are a key component in systems where bacteria, contaminants, or residue must be avoided.

These fittings are frequently installed in hygienic processing lines that also include dairy valves, sampling valves, and flow control mechanisms tailored to strict cleanliness standards.

Types of Sanitary Piping Fittings

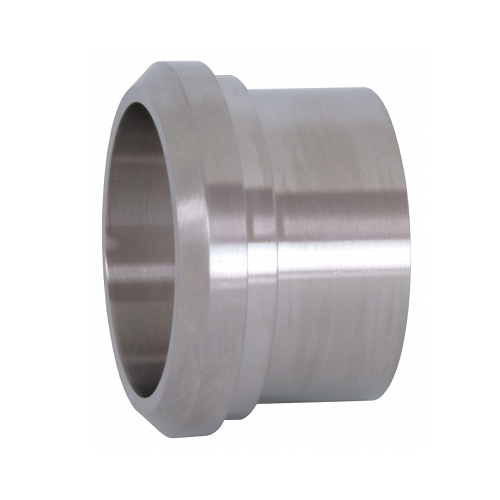

A variety of fittings are used in sanitary systems depending on the type of connection and the process requirements. These include elbows, tees, reducers, clamps, ferrules, adapters, and union components. Fittings may be weld-type, clamp-type, or threaded depending on the ease of disassembly and cleaning needed in the application.

In a typical dairy or pharma pipeline setup, sanitary elbows and reducers often connect to precision-machined stainless steel pipe sections. The entire system is usually complemented by compatible accessories like conical strainers, which are often placed upstream in filtration or product protection zones.

Sanitary Piping Fittings Dimensions

Sanitary fittings are manufactured according to global dimensional standards, ensuring compatibility across brands and systems. Common standards include 3A (United States), ASME BPE (pharma and biotech), DIN (Germany), and ISO (international). These standards define the outer diameter (OD), wall thickness, clamp size, and radius for fittings.

For example, a 1.5-inch sanitary elbow in a CIP system may require a 50.5 mm clamp connection, and this must match the ferrule size and gasket. Correct dimensioning is crucial to maintain seal integrity and flow consistency. In systems where conical strainers are used for particulate control, precise sizing ensures no turbulence or obstruction occurs at the junctions.

Grades of Stainless Steel Used in Sanitary Fittings

Material grade selection directly impacts the durability, corrosion resistance, and compliance of sanitary fittings. The most widely used stainless steel grades include:

-

SS 304: Common in general-purpose food and beverage processing applications.

-

SS 316: Offers enhanced corrosion resistance, especially in contact with acidic or chemical-based solutions, making it suitable for pharmaceutical or chemical handling systems.

-

SS 316L: Preferred in sterile environments due to its low carbon content, which minimizes sensitization during welding.

In certain installations, like high-purity fluid transfer or high-pressure zones, these fittings are paired with SS pipes that offer the same grade, finish, and tolerance, maintaining consistency across the piping network.

Sanitary Piping Fittings Price

Pricing for sanitary fittings is influenced by the stainless steel grade, fitting type, size, surface finish, and whether the fitting meets special standards like ASME BPE or 3A. For example, a 1” SS 304 sanitary elbow may cost significantly less than the same fitting in SS 316L with an electro-polished finish.

Fittings used in pharmaceutical and high-end dairy applications may also require third-party inspection and test certificates, which further affect pricing. When assembling a project scope, many engineers also factor in accessories like sampling valves, strainers, and butterfly valves, which must match the same sanitary design principles as the main fittings.

Choosing a Sanitary Fittings Manufacturer in India

When sourcing sanitary fittings, selecting a reliable and experienced manufacturer is essential. Look for suppliers who follow international standards, offer traceable material certificates, and maintain strict quality controls. Manufacturers should also provide dimensional drawings and support compliance documentation for regulated industries.

For example, if you’re working on a dairy processing line that involves precision connections, it’s important to source from manufacturers who also supply compatible components like stainless steel boiler tubes or conical strainers. This helps ensure compatibility and performance across the entire system.

A good manufacturer will also understand the specific requirements of each sector. In pharmaceutical cleanrooms, for instance, the fittings need to match ASME BPE standards and be suitable for orbital welding. In contrast, food processing systems may rely on clamp-style fittings for ease of disassembly and maintenance.

Applications of Sanitary Fittings

Sanitary fittings are installed across a wide range of hygienic processing systems. In the dairy industry, they connect pipelines that transport milk, cream, whey, and other products while ensuring that there is no bacterial buildup. In the pharmaceutical industry, they form part of fluid transfer lines, ensuring that medicines and solutions are transported in sterile, contamination-free conditions.

These fittings also support product recovery systems and are often installed alongside flow diversion and regulating valves. In beverage plants, they are used in both hot and cold liquid transfer systems, from brewing to bottling.

Conclusion

Sanitary piping fittings are a vital part of any hygienic processing infrastructure. Understanding their types, dimensions, material grades, and cost implications can help engineers, plant managers, and procurement teams make informed decisions. These fittings are more than just connectors—they are key to product safety, process efficiency, and regulatory compliance.

When selecting a manufacturer, it’s beneficial to work with companies that offer a full range of compatible hygienic components, including valves, strainers, and pipe sections. By maintaining dimensional and material consistency throughout the system, you can ensure long-term reliability and performance.

If you are building or upgrading a sanitary system, make sure that every fitting, pipe, and valve is chosen with precision, cleanliness, and compliance in mind.

Our extensive domestic network spans key locations across India

including Mumbai, Delhi, Bangalore, Chennai, and Kolkata. Internationally, our robust footprint extends to countries such as the UAE, United States, Germany, Italy, and Malaysia. This makes us a reliable Stainless Steel Sanitary Tube Supplier, catering to both local and global needs.

When you require premium Stainless Steel Sanitary Tube or Stainless Steel Sanitary Tubing in India, Mahadev Dairy Pharma Fittings is the name you can trust. Our commitment to quality, precision, and excellence ensures our products are the perfect solution for industrial applications.

ASTM-Compliant Tubing and Piping

|

Product |

Description |

|

ASTM A270 Tubing |

Hygienic stainless steel tubes meeting the highest sanitary standards. |

|

ASTM A213 Tube |

Tubes designed for high-temperature applications in power and industrial sectors. |

|

ASTM A213 TP304 Tube |

Premium stainless steel tubes crafted with TP304 grade for strength and versatility. |

|

ASTM A213 TP316 Tube |

High-performance tubes with TP316 grade, ideal for corrosive environments. |

|

ASTM A269 Tubing |

General-purpose stainless steel tubing for a wide range of industries. |

|

ASTM A269 TP304 Tube |

Tubes with excellent mechanical properties for industrial applications. |

|

ASTM A269 TP316 Tube |

Corrosion-resistant TP316 tubing for chemical and food processing. |

|

ASTM A554 Tubing |

Decorative and structural tubing for modern applications. |

|

ASTM A249 Tube |

Welded stainless steel tubes for boilers and heat exchangers. |

|

ASTM A312 TP304 Pipe |

TP304 grade pipes for seamless and welded applications. |

|

ASTM A358 Pipe |

Welded pipes for heavy-duty industrial use. |

|

ASTM A312 Pipe |

Versatile stainless steel pipes for fluid transfer and structural support. |

Features of Stainless Steel Sanitary Tube

- Superior Hygiene: Our tubes are crafted for applications where cleanliness is a priority, ensuring no contamination during fluid transfer.

- Robust Durability: Manufactured with premium-grade stainless steel, our tubes offer excellent corrosion resistance and long-lasting performance.

- Versatile Applications: Ideal for industries such as pharmaceuticals, dairy, food processing, and beverages.

Our Product Portfolio: Sanitary Tube

- Stainless Steel Sanitary Tube

Designed for hygienic applications, these tubes ensure contamination-free fluid transfer in industries like dairy and pharmaceuticals. - Stainless Steel Sanitary Tubing

Available in electropolished and mechanically polished finishes, ideal for aesthetic and functional applications. - Stainless Steel Rectangular Tube

Perfect for structural and decorative purposes, offering strength and a sleek appearance. - Stainless Steel Tube

High-quality tubes for diverse applications, ensuring durability and corrosion resistance. - Stainless Steel Heat Exchanger Tube

Engineered for superior thermal conductivity and efficiency in heat transfer systems.

Sanitary Tube Fitting : Enhancing Hygienic Connections

At Mahadev Dairy Pharma Fittings, we also provide a wide range of Sanitary Tube Fittings in India that perfectly complement our tubes. These fittings are engineered for leak-proof, hygienic connections and include:

- TC Liners

- DIN Unions

- Rotary and Fixed Spray Balls

With our comprehensive solutions, we ensure that your sanitary systems operate efficiently and meet international standards.

Domestic Reach for Sanitary Tubing

We supply high-quality Stainless Steel Sanitary Tube products to major cities and industrial hubs across the country:

|

Region |

Key Cities |

|

Western India |

Mumbai, Pune, Ahmedabad, Surat, Vadodara, Nashik, Bhiwandi, Rajkot, Bhavnagar |

|

Northern India |

Delhi, Faridabad, Chandigarh, Jaipur, Bikaner, Lucknow |

|

Southern India |

Bangalore, Hyderabad, Chennai, Kochi (Cochin), Tirupur, Mangalore |

|

Central India |

Nagpur, Indore, Bhopal, Raipur |

|

Eastern India |

Kolkata, Bhubaneswar, Siliguri |

Our Comprehensive Product Range

At Mahadev Dairy Pharma Fittings, we take pride in offering high-quality Stainless Steel Sanitary Tube, Stainless Steel Sanitary Tubing, and a wide range of fittings tailored for various industrial applications. Our products are designed to ensure reliability, hygiene, and efficiency, making them ideal for demanding industries like pharmaceuticals, dairy, and food processing.

High-Quality Stainless Steel Sanitary Tube: Global and Domestic Applications

Our extensive product range includes a variety of fittings and pipes that meet international standards for quality and durability. These include:

Fittings and Pipes for Sanitary Systems

|

Fittings and Pipes |

Description |

|

Camlock Fittings |

Quick-connect couplings for secure and efficient fluid transfer. |

|

Compression Tube Fittings |

Leak-proof fittings for precise instrumentation and control systems. |

|

Instrumentation Pipe Fittings |

Reliable fittings for high-pressure and high-temperature applications. |

|

BioPharm (BPE) Fittings |

Designed for strict pharmaceutical and biotech standards, ensuring sterile environments. |

|

Tri-Clamp Fittings |

Easy-to-install and hygienic fittings for seamless connections. |

|

Sanitary Butt-Weld Fittings |

Durable fittings for permanent, leak-free piping systems. |

|

DIN 11851 Fittings |

Standardized fittings ideal for European-style piping systems. |

|

DIN 32676 Clamp Fittings |

Efficient clamp fittings for hygienic fluid handling systems. |

|

Bevel Seat Fittings |

Threaded fittings for secure and clean connections in sanitary applications. |

|

I-Line Fittings |

High-performance fittings for heavy-duty sanitary applications. |

|

Q-Line Fittings |

Precision-engineered fittings for seamless fluid transfer. |

|

Tube Hangers |

Sturdy and hygienic supports for stainless steel tubes in various installations. |

|

ASTM Tubes and Pipes |

Manufactured to ASTM standards, offering superior strength, corrosion resistance, and durability. |

|

Electropolished Tubes |

Smooth, clean, and corrosion-resistant tubes ideal for critical applications. |

|

Mechanically Polished Pipes |

Durable pipes with a refined finish for industrial and decorative purposes. |