Mahadev Dairy Pharma Fiting is a trusted High Purity Stainless Steel Tubing Manufacturer in India, supplying Ultra High Purity (UHP) stainless steel tubing for semiconductor, microelectronics, and cleanroom gas distribution piping systems. Our tubing is designed to meet strict purity, dimensional accuracy, and surface finish requirements for critical applications.

Ultra High Purity Stainless Steel Tubing

Ultra High Purity stainless steel tubing is widely used in semiconductor fabrication units, microelectronics cleanrooms, and nitrogen gas piping systems. These tubes are manufactured to minimize particle generation and prevent contamination during gas transfer.

Our UHP tubing ensures reliable performance in high purity gas distribution systems where cleanliness and consistency are essential.

Mahadev Dairy Pharma Fiting – Ultra High Purity Stainless Steel Tubing Datasheet

Product Overview

Mahadev Dairy Pharma Fiting is a trusted High Purity Stainless Steel Tubing Manufacturer in India, supplying UHP tubing for semiconductor, microelectronics, cleanroom, and high purity gas distribution systems. Our tubing is designed to meet ASME BPE, ASTM, and ASME A270 standards, ensuring ultra-clean surfaces, precise dimensions, and long-term reliability.

Specifications

| Feature | Specification |

| Material Grades | SS 304, 304L (1.4307), SS 316, 316L (1.4404) |

| Manufacturing Process | Seamless, cold drawn, solution annealed |

| Standards | ASME BPE, ASTM A270, ASME SA270 |

| Surface Finish | Electropolished (EP), Mechanically Polished (MP), Bright Annealed (BA) |

| Surface Roughness (Ra) | ID: 0.38 – 0.80 μm, OD: < 0.80 μm |

| Dimensions | OD: ¼” – 6″ (custom available), Wall thickness: per ASME BPE |

| Application | Cleanroom gas systems, Nitrogen piping, Semiconductor fabs, Microelectronics, WFI, SIP, CIP |

Application-wise Material & Surface Finish

| Application | Material Grade | ID Surface Finish | OD Surface Finish | Ra Value (ID μm) | Ra Value (OD μm) |

| Soft Water | 304L / 1.4307 316L / 1.4404 | MP / EP | MP | <0.50 / 0.38 | <0.80 |

| Potable Water / Purified Water / WFI / Pure Steam / SIP | 316L / 1.4404 | EP | MP | 0.38 | <0.80 |

| CIP | 316L / 1.4404 | MP | MP | <0.50 | <0.80 |

| Process Chemicals | 316L / 1.4404 | BA / MP / EP | MP | <0.80 / 0.50 / 0.38 | <0.80 |

| Compressed Air / Gas | 304L / 1.4307 316L / 1.4404 | BA | MP | <0.80 | <0.80 |

Notes:

- 316L / 1.4404 is used when ozone is present in the disinfection system.

- 304L / 1.4307 is suitable for chloride concentration up to 500 mg/L and free chlorine up to 5 mg/L at room temperature. If temperature exceeds 50°C, use 316L.

- 316L / 1.4404 is required for chloride concentration 500–2000 mg/L with free chlorine ≤5 mg/L.

- 316L / 1.4404 is mandatory for temperatures >50°C.

High Purity Stainless Steel Tubing Types

- Ultra High Purity Seamless Stainless Steel Tubing

- Electropolished Stainless Steel Tubing

- Mechanically Polished BPE Tubing

- Sanitary Grade High Purity Tubing

- Cleanroom Gas Distribution Tubing

Chemical Composition of UHP Stainless Steel Tubing

UHP stainless steel tubing is manufactured with controlled chemical composition to provide excellent corrosion resistance and long service life. Low carbon content and precise alloying elements ensure suitability for ultra-clean environments.

High Purity Stainless Steel Seamless Tube Surface Treatment

Surface treatments enhance cleanliness and reduce contamination risk:

- Electropolishing for ultra-smooth internal surfaces

- Mechanical polishing for controlled finish

- Pickling and passivation for corrosion resistance

- Bright annealing for clean and smooth appearance

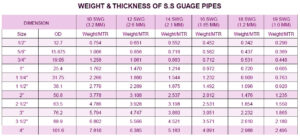

Sizes of Ultrahigh-Purity Stainless Steel Tubes

- Outer Diameter: ¼ inch to 6 inch

- Length: Standard, random, or customized

- Wall Thickness: As per ASME BPE and ASTM standards

Custom sizes are available based on project requirements.

316 SS Ultra High Purity Tubing Tolerance

SS 316 UHP tubing is produced with tight dimensional tolerances to ensure precise installation, compatibility with orbital welding, and leak-free performance in cleanroom gas piping systems.

SS Electropolished BPE Tubing Sizes

Electropolished BPE tubing is available in standard ASME BPE sizes with low surface roughness, making it suitable for semiconductor and microelectronics applications.

Stainless Steel Mechanically Polished BPE Tubing Sizes

Mechanically polished BPE tubing provides a cost-effective solution while maintaining high cleanliness levels for sanitary and cleanroom installations.

SS 304 High Purity Tubing Test

Each lot of SS 304 high purity tubing undergoes rigorous quality testing, including chemical analysis, dimensional inspection, surface finish checks, and pressure testing.

High Purity Stainless Steel 304 Tubing Standards

Manufactured in accordance with:

- ASTM A270

- ASME SA270

- ASME BPE

- ASTM A213 and ASTM A269

Wall Thickness of Sanitary Stainless Steel Tube

Wall thickness is available as per standard sanitary tubing requirements and can be customized based on application needs.

High Purity Stainless Steel Tubing Price List

The price of high purity stainless steel tubing depends on grade, size, wall thickness, surface finish, and quantity.

Contact Mahadev Dairy Pharma Fiting for the latest pricing details.

SS 316 UHP Tube HS Code

HSN Code: 7304

(Seamless stainless steel tubes and pipes)

SS Ultrahigh-Purity Tube Dimensions

Dimensions are supplied according to ASME BPE and ASTM standards or as per customer drawings.

Surface Finish of Welded High Purity Stainless Steel Pipe

- Smooth internal weld profile

- Clean and uniform surface finish

- Suitable for semiconductor and cleanroom gas applications

ASME A270 UHP Seamless Tube Physical Properties

- High tensile strength

- Excellent elongation

- Superior corrosion resistance

- Long operational life in high purity environments

Applications of High Purity Stainless Steel Tubing

- Semiconductor manufacturing plants

- Microelectronics cleanrooms

- Nitrogen gas piping systems

- High purity gas distribution systems

- Pharmaceutical and laboratory cleanrooms

Why Choose Mahadev Dairy Pharma Fiting?

- Reliable High Purity Stainless Steel Tubing Manufacturer in India

- Expertise in ultra high purity and cleanroom piping solutions

- Strict quality and cleanliness control

- Custom manufacturing capabilities

- Trusted supplier for critical industries