How to Calculate Channel Weight Easily:

In structural steel fabrication and construction, C channels (also called ISMC – Indian Standard Medium Channel) are among the most commonly used steel profiles. But to estimate material costs, transportation loads, and fabrication feasibility, it’s crucial to calculate the weight of C channels accurately.

Industries such as dairy, pharmaceuticals, and petrochemicals rely on precision tubing. For pharmaceutical-grade pipes, our ASTM A270 Tubing inventory meets the strictest hygiene standards. We also offer Stainless Steel Hygienic Electropolished Pipes that are ideal for cleanroom and sterile environments.

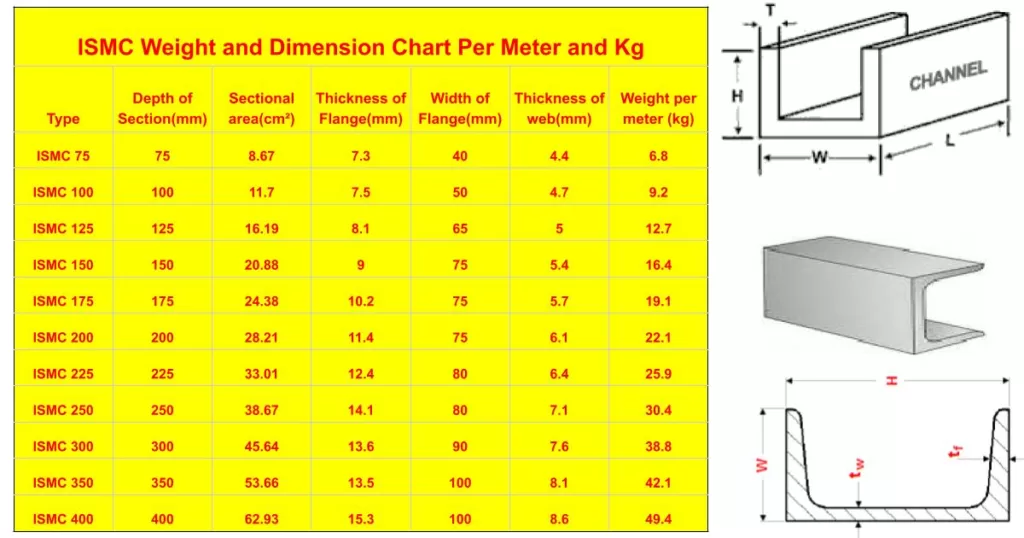

This ISMC chart is widely used for structural steel calculations in both civil and industrial projects. If you’re also using rectangular profiles in your application, we recommend visiting our Rectangular Tube Manufacturer section to explore sizing options.

Knowing the weight is essential whether you’re building a platform frame or connecting heat exchanger piping. For those working in specialized environments like high-temperature systems, refer to our Stainless Steel Boiler Tube Supplier page for compatible options.

In this guide, we’ll explore:

- What is a C channel?

- C channel weight calculator formula

- C channel weight chart (in kg/m)

- Factors affecting channel weight

- How to use the chart for MS, SS, and GI channels

Let’s begin by understanding what a C channel actually is.

What is a C Channel?

A C channel, or Channel Section, is a steel profile with a cross-sectional shape that looks like the letter “C.” These channels are widely used in:

- Structural frames

- Industrial sheds

- Machinery supports

- Vehicle chassis

- Construction projects

They’re manufactured in different sizes, thicknesses, and materials like mild steel (MS), stainless steel (SS), and galvanized iron (GI).

C Channel Weight Calculator Formula

To calculate the weight of a C channel manually, you can use the steel weight formula:

Weight (kg/m) = Sectional Area (mm²) × Density of Steel (7.85 g/cm³) / 1,000

But for simplicity, most use the formula below, which factors in the dimensions:

✅ Simplified C Channel Weight Formula:

Weight (kg/m) = Width × Height × Thickness × 0.00785

Where:

- Width, Height, and Thickness are in mm

- 0.00785 is the density of steel in g/mm³

C Channel Weight Chart (in kg/m)

Here’s a standard ISMC C channel weight chart based on Indian Standards. This helps you avoid manual calculations.

C Channel Weight Chart (ISMC)

| ISMC Size | Depth (mm) | Width (mm) | Thickness (mm) | Weight (kg/m) |

|---|---|---|---|---|

| ISMC 75 | 75 | 40 | 4.8 | 7.1 |

| ISMC 100 | 100 | 50 | 5.0 | 9.6 |

| ISMC 125 | 125 | 65 | 5.3 | 13.1 |

| ISMC 150 | 150 | 75 | 5.7 | 16.8 |

| ISMC 175 | 175 | 75 | 6.0 | 19.6 |

| ISMC 200 | 200 | 75 | 6.2 | 22.4 |

| ISMC 225 | 225 | 80 | 6.5 | 25.5 |

| ISMC 250 | 250 | 82 | 7.0 | 29.5 |

| ISMC 300 | 300 | 90 | 7.8 | 36.3 |

| ISMC 400 | 400 | 100 | 8.8 | 50.1 |

🔗 Explore more on ISMC weight chart here (Internal link placeholder)

C Channel Weight Calculator Online

For quick results without manual math, you can use a C channel weight calculator tool. These tools calculate weight based on:

- Channel size

- Material (MS, SS, GI)

- Length

Here’s how to use it:

Steps to Use a Channel Weight Calculator:

- Select material type (e.g., MS – Mild Steel)

- Enter the C channel size (e.g., 150x75x5.7 mm)

- Enter the total length (e.g., 6 meters)

- Click Calculate

- Get weight in kg or tons

C Channel Weight Calculator

C Channel Weight per Meter

Below is a quick table of c channel weight per meter for popular sizes:

| Channel Size | Weight (kg/m) |

|---|---|

| 75×40 | 7.1 |

| 100×50 | 9.6 |

| 150×75 | 16.8 |

| 200×75 | 22.4 |

| 250×82 | 29.5 |

For lengths in feet, multiply the weight per meter by 0.3048 to get per foot weight.

C Channel Weight in Stainless Steel vs Mild Steel vs GI

| Material | Density (g/cm³) | Weight (kg/m) | Notes |

|---|---|---|---|

| Mild Steel | 7.85 | Base reference | Most commonly used |

| Stainless Steel | 8.0 | Slightly heavier | Used in pharma/food industry |

| Galvanized Iron (GI) | 7.85 | Same as MS | Coated for rust resistance |

Why Accurate Channel Weight Matters

- Helps in material cost estimation

- Aids in transportation planning

- Ensures structural safety

- Required for steel fabrication and welding

Use Cases of C Channels in Industries

- Construction: Framing, trusses, and columns

- Fabrication: Machinery base frames and racks

- Automotive: Chassis and support frames

- Railways: Bridge platforms and wagons

Conclusion

Whether you’re working with mild steel, stainless steel, or galvanized C channels, knowing how to calculate weight accurately using a C channel weight calculator or chart is essential. It simplifies procurement, helps reduce waste, and boosts overall project efficiency.

Bookmark this guide and use the c channel weight chart whenever you need a quick reference.

FAQs

Q1. What is the unit weight of ISMC 150?

ISMC 150 has a unit weight of 16.8 kg/m.

Q2. How do you calculate the weight of a steel channel?

Weight = Width × Height × Thickness × 0.00785

Q3. Which is heavier – stainless steel or mild steel channel?

Stainless steel is slightly heavier than mild steel due to higher density (8.0 g/cm³ vs. 7.85 g/cm³).

Q4. Where can I get a free c channel weight calculator?

You can use our free C Channel Weight Calculator tool online.

Q5. What sizes are available in standard C channels?

Standard sizes range from ISMC 75 to ISMC 400 based on IS standards.