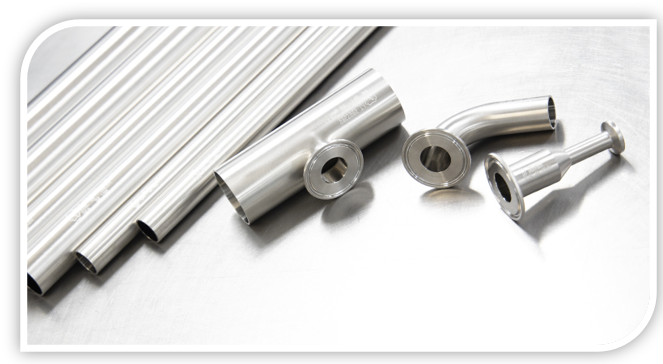

When it comes to the dairy and pharmaceutical industries, choosing the right tube fittings is essential for maintaining product safety and operational efficiency. At Mahadev Dairy Pharma Fittings, we understand the importance of high-quality fittings that can stand up to the rigorous demands of these sectors. Our tube fittings are built to meet industry standards like 3A, BS 4825, ASME BPE, ISO, and SMS, ensuring both durability and hygiene for your operations.

Mahadev Dairy Pharma Fittings are trusted by manufacturers in both the dairy and pharmaceutical industries for their outstanding performance. Here’s why:

- Compliance with International Standards: Our tube fittings meet 3A, BS 4825, ASME BPE, ISO, and SMS standards, ensuring that they are of the highest quality and perfectly suited for sanitary applications.

- Long-lasting Durability: Made from stainless steel, Mahadev fittings are resistant to corrosion and wear, making them ideal for both dairy and pharmaceutical industries where hygiene and cleanliness are paramount.

- Precision Manufacturing: We offer fittings that are designed with tight tolerances, ensuring that every connection is secure, leak-proof, and sanitary.

- Easy to Install and Maintain: With Mahadev fittings, you can save time on installation and maintenance. They’re designed to be simple and efficient, allowing your team to focus on what matters most—producing high-quality products.

Ideal for Dairy and Pharmaceutical Applications

Whether you’re setting up a milk processing line or managing a pharmaceutical production facility, Mahadev tube fittings provide the perfect solution. Our fittings support safe and efficient flow, ensuring that your operations run smoothly without compromising on hygiene or safety.

Why Choose Us?

At Mahadev, we are committed to providing products that meet the highest standards. Our tube fittings are manufactured to ensure smooth, reliable performance in the most demanding environments. We focus on creating solutions that help your business maintain efficiency while complying with all necessary regulations.

Get in Touch with Us

If you need tube fittings that guarantee reliability and performance, Mahadev Dairy Pharma Fittings is the name you can trust. Reach out today for a quote or to discuss your specific requirements.

Email:- mahadevdairyp@gmail.com

Phone:- +919685817434

Website: – mahadevdairypharmafitting.com

PRODUCTS 3A – BS 4825 – ASME BPE – ISO – SMS TUBE FITTING

The use of Tube Fittings for Dairy and Pharma is vital for preventing contamination and ensuring the purity of the final product. Mahadev’s dedication to excellence in this area is a significant advantage for businesses looking for trustworthy suppliers.

Key Takeaways

- High-quality tube fittings are essential for the dairy and pharmaceutical industries.

- Mahadev provides reliable and sanitary tube fittings.

- The use of proper tube fittings prevents contamination.

- Mahadev’s products meet stringent industry standards.

- Trustworthy suppliers like Mahadev are crucial for business operations.

Understanding High-Quality Tube Fittings for Specialized Industries

In the realm of dairy and pharmaceutical industries, the significance of high-quality tube fittings cannot be overstated. These components are crucial for maintaining the integrity and safety of processing systems.

Tube fittings are used extensively in these industries for various applications, including the transfer of sensitive products and the connection of equipment. The quality of these fittings directly impacts the overall safety and efficiency of the processing operations.

Critical Role of Tube Fittings in Dairy and Pharmaceutical Applications

Tube fittings in dairy and pharmaceutical applications are subject to stringent requirements due to the nature of the products being processed. Sanitary Tube Fittings and ASME BPE Tube Fittings are designed to meet these demands, ensuring that the products are not contaminated during processing.

The use of high-quality tube fittings is essential for preventing contamination and ensuring compliance with industry standards such as 3A Sanitary Standards.

Why Quality and Compliance Matter in Sanitary Processing

Compliance with industry standards is critical for ensuring the quality and safety of products in dairy and pharmaceutical processing.

“The quality of tube fittings is paramount for maintaining sanitary conditions in processing facilities.”

| Industry Standard | Description | Application |

| 3A Sanitary Standards | Standards for sanitary equipment design | Dairy and Food Processing |

| ASME BPE | Standards for bioprocessing equipment | Pharmaceutical and Biotechnology |

By adhering to these standards and using high-quality tube fittings, industries can ensure the integrity of their products and the safety of their processing operations.

PRODUCTS3A BS4825 ASME – BPE ISO – SMS TUBE FITTING: A Comprehensive Overview

Mahadev’s PRODUCTS3A BS4825 ASME – BPE ISO – SMS TUBE FITTING is designed to meet the rigorous demands of the dairy and pharmaceutical industries. These fittings are crucial for ensuring the integrity and efficiency of processing systems.

Key Features and Technical Specifications of Mahadev Fittings

The Mahadev Tube Fittings are engineered with precision to offer superior performance. Key features include:

- Compliance with multiple international standards such as 3A, BS4825, ASME-BPE, ISO, and SMS.

- High-quality Stainless Steel construction for durability and resistance to corrosion.

- Precision engineering to ensure leak-tight connections and smooth internal surfaces.

The technical specifications of these Tube Fittings are designed to meet the exacting requirements of sanitary processing. This includes precise dimensions, smooth finishes, and compatibility with various tubing systems.

Material Composition and Engineering Excellence

The material composition of Mahadev’s Stainless Steel Tube Fittings is a critical factor in their performance. The use of high-grade stainless steel ensures:

- Resistance to corrosion and chemical attack.

- Durability and longevity, reducing the need for frequent replacements.

- Compatibility with a wide range of process media and operating conditions.

The engineering excellence that goes into these fittings is evident in their precise manufacturing and quality control processes. This ensures that every fitting meets the highest standards of quality and performance.

Industry Standards and Compliance Requirements

To guarantee the integrity of their operations, manufacturers in the dairy and pharmaceutical sectors must adhere to specific industry standards for tube fittings. These standards ensure the quality, safety, and reliability of the fittings used in various applications.

3A Sanitary Standards for Dairy Equipment

The 3A Sanitary Standards are crucial for dairy equipment, including tube fittings. These standards, developed by the 3-A Sanitary Standards organization, focus on the design and fabrication of equipment to ensure sanitary conditions. Mahadev’s tube fittings comply with these standards, ensuring they are suitable for use in dairy processing.

BS4825 British Standard for Stainless Steel Tubing

BS4825 is a British Standard that specifies requirements for stainless steel tubing used in the food and dairy industries. Mahadev’s tube fittings are manufactured to meet or exceed BS4825 standards, ensuring compatibility and reliability with existing systems.

ASME-BPE Standards for Bioprocessing Equipment

The ASME-BPE (American Society of Mechanical Engineers – Bioprocessing Equipment) standards provide guidelines for the design, materials, fabrication, and testing of bioprocessing equipment. Mahadev’s adherence to ASME-BPE standards ensures their tube fittings meet the rigorous requirements of the bioprocessing industry.

ISO and SMS International Compliance Specifications

ISO (International Organization for Standardization) and SMS (Sanitary Machinery and Systems) standards are internationally recognized specifications that ensure the quality and safety of equipment used in various industries. Mahadev’s tube fittings comply with relevant ISO and SMS standards, facilitating their use in global markets.

| Standard | Description | Industry |

| 3A Sanitary Standards | Focuses on sanitary conditions for dairy equipment | Dairy |

| BS4825 | Specifies requirements for stainless steel tubing | Food and Dairy |

| ASME-BPE | Guidelines for bioprocessing equipment design and testing | Bioprocessing |

| ISO and SMS | Internationally recognized standards for equipment quality and safety | Global |

By complying with these industry standards, Mahadev ensures that their tube fittings are reliable, safe, and suitable for use in various applications across the dairy and pharmaceutical industries.

Applications in the Dairy Industry

The use of sanitary tube fittings is vital in dairy applications, ensuring product purity and safety. Mahadev’s tube fittings are designed to meet the stringent requirements of the dairy industry, providing reliable and efficient solutions for various dairy processing needs.

Milk Processing and Transfer Systems

In milk processing and transfer systems, sanitary tube fittings play a crucial role in maintaining the integrity of the product. Mahadev’s fittings are engineered to prevent contamination and ensure smooth operation, thereby enhancing the overall efficiency of milk processing plants. The use of high-quality materials and precise manufacturing processes ensures that these fittings meet the highest standards of quality and reliability.

Cheese and Yogurt Production Lines

For cheese and yogurt production lines, Mahadev’s dairy industry tube fittings are designed to facilitate smooth and efficient processing. These fittings help in maintaining the precise conditions required for the production of high-quality cheese and yogurt, ensuring consistency and purity throughout the production process.

CIP (Clean-in-Place) and Sanitation Systems

CIP systems are critical in dairy processing for maintaining sanitary conditions. Mahadev’s tube fittings are designed to integrate seamlessly with CIP systems, ensuring thorough cleaning and sanitation. This integration helps in preventing bacterial growth and contamination, thereby safeguarding the quality of dairy products.

In conclusion, Mahadev’s tube fittings are indispensable in the dairy industry, supporting various applications from milk processing to CIP systems. Their commitment to quality and sanitation ensures that dairy producers can rely on these fittings for efficient and safe processing.

Pharmaceutical Applications and Benefits

The pharmaceutical sector demands tube fittings that meet stringent standards for sterile processing and compliance. Mahadev’s tube fittings are engineered to provide the highest level of quality and reliability for pharmaceutical applications.

Sterile Processing and Aseptic Manufacturing

In sterile processing and aseptic manufacturing, the integrity of the product is paramount. Mahadev’s Pharmaceutical Tube Fittings are designed to ensure a sterile environment, minimizing the risk of contamination. These fittings are manufactured under strict quality control protocols to meet the required standards.

Biotech, Laboratory, and Research Applications

Biotechnology, laboratory, and research applications require precision and reliability. Mahadev’s tube fittings are used in various biotech processes, including fermentation and cell culture, where maintaining sterility is crucial. The fittings’ design ensures smooth operation and ease of use in laboratory settings.

Compliance with GMP and FDA Requirements

Compliance with Good Manufacturing Practice (GMP) and FDA requirements is essential in the pharmaceutical industry. Mahadev’s tube fittings are designed with GMP Compliance in mind, ensuring that all products meet or exceed regulatory standards. This compliance is critical for pharmaceutical manufacturers to avoid costly rework and ensure product safety.

As stated by a leading industry expert, “The quality of tube fittings directly impacts the overall quality and safety of pharmaceutical products.” This underscores the importance of selecting the right fittings for pharmaceutical applications.

Types of Mahadev Tube Fittings for Specialized Applications

Mahadev offers a diverse range of tube fittings designed to meet the stringent requirements of specialized industries. Their products are engineered to provide reliable, leak-tight connections in various applications, from dairy processing to pharmaceutical manufacturing.

Sanitary Clamp Fittings and Tri-Clamps

Sanitary clamp fittings, including tri-clamps, are widely used in industries where hygiene is paramount. These fittings provide a secure, easy-to-clean connection that meets sanitary standards. Mahadev’s sanitary clamp fittings are designed for quick installation and removal, facilitating maintenance and reducing downtime.

Types of Tube Fittings

Orbital Weld Fittings and Butt-Weld Options

For applications requiring high-integrity welds, Mahadev offers orbital weld fittings and butt-weld options. These fittings are designed to withstand the rigors of high-temperature and high-pressure processes, ensuring a strong, durable connection. Orbital welding technology minimizes the risk of contamination, making it ideal for sterile processing environments.

Threaded and Bevel Seat Fittings

Threaded and bevel seat fittings provide a versatile solution for various piping configurations. Mahadev’s threaded fittings offer a secure connection with easy installation, while bevel seat fittings ensure a smooth, crevice-free joint. These fittings are suitable for a range of applications, from fluid handling to gas distribution systems.

Custom Engineered Solutions for Complex Requirements

Mahadev also provides custom engineered solutions to address complex or unique fitting requirements. Their team of experts works closely with clients to design and manufacture fittings that meet specific application needs, ensuring optimal performance and compliance with industry standards.

| Fitting Type | Application | Key Benefits |

| Sanitary Clamp Fittings | Dairy, Pharmaceutical | Easy to clean, meets sanitary standards |

| Orbital Weld Fittings | Sterile Processing, High-Pressure Systems | High-integrity welds, minimizes contamination risk |

| Threaded and Bevel Seat Fittings | Fluid Handling, Gas Distribution | Secure connection, smooth joint |

| Custom Engineered Fittings | Complex or Unique Requirements | Tailored solution, optimal performance |

Material Selection and Surface Finish Options

Material selection and surface finish options are critical factors that influence the functionality, safety, and durability of tube fitting sanitary piping processing . The choice of material and surface finish can significantly impact the performance, cleanliness, and reliability of processing systems.

316L and Other Stainless Steel Grades for Different Applications

The use of 316L stainless steel is prevalent in tube fittings for dairy and pharmaceutical applications due to its corrosion resistance, durability, and compatibility with cleaning agents. Other stainless steel grades may be used depending on specific application requirements, such as higher temperature resistance or enhanced mechanical properties.

Surface Finish Requirements: From 32Ra to Electropolished

Surface finish is a critical aspect of tube fittings, with options ranging from mechanical finishes like 32Ra to more advanced processes such as electropolishing. Electropolishing, for instance, provides a high-luster finish that enhances corrosion resistance and facilitates cleaning.

Impact on Product Quality, Flow Characteristics, and System Longevity

The material and surface finish of tube fittings directly affect product quality by preventing contamination, influence flow characteristics by reducing friction and turbulence, and impact system longevity by withstanding corrosive environments and mechanical stress.

By carefully selecting the appropriate material and surface finish for tube fittings, manufacturers can ensure compliance with industry standards, enhance operational efficiency, and maintain product integrity.

Quality Assurance and Testing Procedures

Mahadev’s commitment to excellence is reflected in our comprehensive quality assurance and testing procedures for tube fittings. Ensuring the reliability and performance of our products is paramount in the dairy and pharmaceutical industries, where hygiene and precision are critical.

Quality Assurance for Tube Fittings

Material Certification and Traceability

At Mahadev, we understand the importance of material certification and traceability. Our tube fittings are made from high-quality materials that are certified to meet or exceed industry standards. We maintain detailed records of material sourcing, allowing for complete traceability throughout the production process. This ensures that our products not only meet but exceed customer expectations for quality and reliability.

Key aspects of our material certification include:

- Certification of material composition

- Traceability of materials to their source

- Compliance with industry standards such as 316L stainless steel

Inspection Methods and Quality Control Protocols

Our quality control protocols are designed to ensure that every product meets our stringent quality standards. We employ a range of inspection methods, including visual inspection, dimensional checks, and surface finish analysis. Our quality control team is trained to identify even the smallest defects, ensuring that only perfect products reach our customers.

Some of the inspection methods we use include:

- Visual inspection for surface defects

- Dimensional checks to ensure precision

- Surface finish analysis for compliance with specifications

Performance Testing and Validation Procedures

Performance testing is a critical component of our quality assurance process. We conduct rigorous testing to validate the performance of our tube fittings under various conditions. This includes pressure testing, leakage testing, and compatibility testing with different media. Our goal is to ensure that our products perform flawlessly in real-world applications.

Examples of our performance testing include:

| Test Type | Description | Standard Compliance |

| Pressure Testing | Testing for withstand pressure | ASME-BPE |

| Leakage Testing | Checking for leaks under various conditions | ISO Standards |

| Application | Grade | Surface Finish | Finish Value Ra (μm) | ||

| ID | OD | ID | OD | ||

| Soft water | 304 L / 1.4307 / 316L / 1.4404 | MP/EP | MP | < 0.5/0.38 | < 0.8 |

| Potable water/ Purified water / WFI/ Pure steam/ SIP | 316L / 1.4404 | EP | MP | 0.38 | < 0.8 |

| CIP | 316L / 1.4404 | MP | MP | < 0.5 | < 0.8 |

| Process chemical | 316L / 1.4404 | BA/MP/EP | MP | < 0.8/0.5/0.38 | < 0.8 |

| Compressed air / GAS | 304 L / 1.4307 316L / 1.4404 | BA | MP | < 0.8 | < 0.8 |

- NOTE:

[1] 316L / 1.4404 is used when ozone is used in disinfection system

[2] 304L / 1.4307 is resistant to crevice and pitting type corrosion when chloride concentration is up to 500 mg/l with free chlorine concentration up to 5 mg/l

at room temperature. If temp >50 ⁰C then use 316L/1.4404

[3] 316L / 1.4404 is used when chloride concentration is above 500 mg/l – 2000 mg/l with free chlorine concentration upto 5 mg/l.

[4] 316L / 1.4404 is used when temperature is >50 ⁰C.

Conclusion: Ensuring Reliability with Mahadev Dairy Pharma Fittings

In the dairy and pharmaceutical industries, the importance of sanitary Tube Fittings cannot be overstated. Mahadev Dairy Pharma Fittings have emerged as a trusted solution, meeting the stringent requirements of these specialized sectors. By adhering to international standards such as 3A, BS4825, ASME-BPE, ISO, and SMS, Mahadev ensures the delivery of High-Quality Fittings that are crucial for maintaining the integrity of processing systems.

The commitment to quality, compliance, and customer satisfaction has positioned Mahadev as a leading supplier of tube fittings. Their products are designed to withstand the rigorous demands of dairy and pharmaceutical processing, including CIP and sanitation systems, sterile processing, and aseptic manufacturing. By choosing Mahadev Dairy Pharma Fittings, industries can rely on the durability and performance of their equipment, minimizing downtime and optimizing production.

With a focus on material selection, surface Mechanical / Electro polished finish options, and rigorous quality assurance, Mahadev Dairy Pharma Fittings provide a comprehensive solution for industries requiring SS EP Hygienic Tube Fittings. As the demand for high-quality dairy and pharmaceutical products continues to grow, the role of trusted suppliers like Mahadev will remain pivotal in ensuring the integrity and efficiency of processing operations.

FAQ

What are the industry standards that Mahadev’s tube fittings comply with?

Mahadev’s tube fittings comply with various industry standards, including 3A Sanitary Standards, BS4825, ASME-BPE, ISO, and SMS, ensuring their reliability and quality in dairy and pharmaceutical applications.

What materials are used in the manufacture of Mahadev’s tube fittings?

Mahadev’s tube fittings are made from high-quality materials, including 316L and other stainless steel grades, which are selected based on the specific requirements of the application, ensuring durability and resistance to corrosion.

What surface finish options are available for Mahadev’s tube fittings?

Mahadev offers various surface finish options for their tube fittings, ranging from 32Ra to electropolished, which impact product quality, flow characteristics, and system longevity.

How does Mahadev ensure the quality of their tube fittings?

Mahadev ensures the quality of their tube fittings through rigorous testing and validation procedures, including material certification and traceability, inspection methods, and quality control protocols.

What types of tube fittings are available from Mahadev?

Mahadev offers a range of tube fittings, including sanitary clamp fittings, orbital weld fittings, threaded and bevel seat fittings, and custom engineered solutions, catering to diverse application needs.

Can Mahadev’s tube fittings be used in high-pressure applications?

Yes, Mahadev’s tube fittings are designed to withstand various operating conditions, including high-pressure applications, ensuring their reliability and performance.

Are Mahadev’s tube fittings compliant with GMP and FDA requirements?

Yes, Mahadev’s tube fittings are designed to meet GMP and FDA requirements, making them suitable for use in pharmaceutical applications where compliance with these regulations is mandatory.

What is the significance of 3A Sanitary Standards in dairy equipment?

3A Sanitary Standards play a crucial role in ensuring the sanitary design and performance of dairy equipment, including tube fittings, to prevent contamination and ensure the quality of dairy products.

How do Mahadev’s tube fittings contribute to efficient processing in dairy and pharmaceutical applications?

Mahadev’s tube fittings are designed to provide leak-tight connections, resist corrosion, and withstand various operating conditions, thereby contributing to efficient and sanitary processing in dairy and pharmaceutical applications.

Stainless Steel Sanitary Valves Supplier and Manufacturer

In industries where hygiene and product purity are non-negotiable, the quality of sanitary valves can make or break your operation. Mahadev Dairy Pharma Fitting stands as India’s premier stainless steel sanitary valves manufacturer and supplier, delivering precision-engineered solutions that meet the stringent requirements of pharmaceutical, food processing, dairy, and chemical industries worldwide. With our comprehensive range of hygienic valves manufactured from premium-grade stainless steel, we ensure optimal flow control, contamination prevention, and regulatory compliance for your most critical processes.

Visit our website: https://mahadevdairypharmafitting.com

Email us: mahadevdairyp@gmail.com

Call us: +91 9685817434