Introduction

In fluid piping systems, one essential component that ensures flow in a single direction while preventing backflow is the non-return valve (NRV). Whether used in water treatment, chemical processing, or pharmaceutical piping, non-return valves protect equipment and maintain the integrity of the system.

Understanding how these valves function, their key advantages, and where they are used is crucial for system engineers, maintenance teams, and plant operators.

What is a Non-Return Valve?

A non-return valve, also known as a check valve, is a mechanical device that allows fluid (liquid or gas) to flow in one direction only. Once the flow reverses, the valve automatically shuts off to stop backflow. This self-actuating feature makes NRVs vital in systems where reverse flow could cause equipment damage or contamination.

How Does a Non-Return Valve Work?

The working principle is simple but effective. NRVs rely on pressure differentials:

- When fluid enters from the inlet side, pressure opens the valve.

- If pressure drops or flow attempts to reverse, gravity, spring force, or backpressure closes the valve.

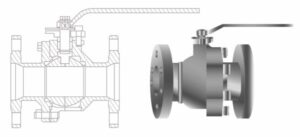

Depending on design, non-return valves can be:

- Swing Type – A disc swings on a hinge or shaft to allow/stop flow.

- Lift Type – The disc lifts vertically to allow flow and drops when flow reverses.

- Ball Type – A ball moves with pressure and seals when reverse pressure appears.

These types vary in response time, installation orientation, and pressure capacity.

Applications of Non-Return Valves

Non-return valves are used across various industries due to their reliability and passive operation.

1. Water Supply & Plumbing

Preventing backflow in municipal water lines or residential plumbing systems ensures water quality and avoids contamination.

2. Pumps and Compressors

Installed at the discharge of pumps or air compressors to prevent reverse flow that can damage rotating equipment.

3. Chemical and Pharmaceutical Plants

In systems transporting aggressive fluids, NRVs protect reactors, tanks, and sensitive equipment from flow reversal.

4. Food and Dairy Processing

In hygienic piping systems, non-return valves prevent cross-contamination, especially where multiple fluids are handled.

Learn more about sanitary piping fittings and hygienic valves used in food-grade industries.

5. Boiler and Steam Systems

They ensure safe pressure operation by stopping reverse steam or condensate flow in industrial heating systems.

Refer to our detailed post on stainless steel boiler tubes for compatible piping materials.

Advantages of Non-Return Valves

- Prevents Backflow – Protects pumps, tanks, and piping from reverse fluid movement.

- Automatic Operation – Requires no manual or external control system.

- Low Maintenance – Few moving parts and simple design ensure long-term reliability.

- Protects Equipment – Avoids costly damage due to sudden pressure reversals or contamination.

- Versatile Design – Available in multiple materials like stainless steel, brass, PVC for various industries.

Materials Used in Non-Return Valves

NRVs can be manufactured in a range of materials depending on fluid type, pressure, and application:

- Stainless Steel (SS 304 / 316) – Used in pharma, dairy, and chemical lines due to corrosion resistance.

- Carbon Steel – Common in industrial and high-pressure environments.

- PVC / Polypropylene – Suitable for low-pressure applications and non-corrosive fluids.

Explore our blog on duplex & super duplex pipe systems if you’re looking for piping materials with extreme corrosion resistance.

Selection Tips for Non-Return Valves

Choosing the right NRV depends on:

- Flow rate and pressure of the system

- Type of media (liquid, gas, aggressive chemicals)

- Installation orientation (horizontal/vertical)

- Size and compatibility with existing piping (refer to standard schedules like Schedule 20 Steel Pipe)

Always ensure the valve meets the pressure and temperature ratings of your process.

Conclusion

Non-return valves are crucial in maintaining the safety, performance, and cleanliness of fluid systems. Their simple yet effective design helps prevent reverse flow without the need for manual intervention, making them ideal for modern automated piping systems.

Whether you’re building a new processing line or upgrading your pipeline safety, choosing the right NRV is essential for long-term reliability.

For industry-compliant stainless steel valves, pipes, and fittings, visit Mahadev Dairy Pharma Fittings – your trusted supplier for hygienic and industrial-grade solutions.

FAQs

1. What is the purpose of a non-return valve?

A non-return valve (NRV) allows fluid to flow in only one direction and prevents backflow. It protects pumps, piping systems, and tanks from contamination or pressure damage caused by reverse flow.

2. Where are non-return valves used?

NRVs are commonly used in plumbing, water supply lines, chemical plants, pharmaceutical industries, steam systems, and food processing lines to ensure unidirectional flow and system safety.

3. Is a check valve the same as a non-return valve?

Yes. The term “check valve” and “non-return valve” are often used interchangeably. Both refer to valves that allow flow in one direction only and prevent reverse flow.

4. Do non-return valves require maintenance?

Non-return valves are low-maintenance components. However, regular inspections are recommended to check for clogging, wear, or failure due to system debris or aggressive media.

5. What materials are non-return valves made from?

NRVs are made from stainless steel, carbon steel, brass, PVC, and other materials based on application needs. For hygienic processes, SS 304 and SS 316 are preferred.

6. What happens if a non-return valve fails?

If an NRV fails, it can allow reverse flow, leading to contamination, pressure loss, or even damage to pumps and equipment. That’s why regular inspections and proper selection are essential.