Introduction: What Are Ferrous and Non-Ferrous Metals?

Metals are classified into two main categories based on their iron content: Ferrous and Non-Ferrous metals. This classification plays a crucial role in determining the metal’s strength, corrosion resistance, magnetic properties, and usage in various industries.

Understanding the difference between these two categories can help you select the right material for construction, manufacturing, piping, or automotive applications.

1. What Are Ferrous Metals?

Ferrous metals are metals that primarily contain iron. They are known for their high strength, durability, and magnetic properties. However, most ferrous metals are susceptible to rust when exposed to moisture—unless they are alloyed with corrosion-resistant elements like chromium.

Common Ferrous Metals:

| Ferrous Metal | Properties | Applications |

|---|---|---|

| Carbon Steel | High strength, low cost | Construction, pipelines, tools |

| Cast Iron | Hard, brittle, good vibration damping | Machine bases, cookware |

| Wrought Iron | Malleable, corrosion-resistant | Fencing, gates |

| Alloy Steel | High tensile strength, corrosion-resistant | Aerospace, automotive, tools |

2. What Are Non-Ferrous Metals?

Non-Ferrous metals do not contain iron. They are generally lighter, more corrosion-resistant, and non-magnetic. These metals are ideal for applications where weight, conductivity, and resistance to rust are essential.

Common Non-Ferrous Metals:

| Non-Ferrous Metal | Properties | Applications |

|---|---|---|

| Aluminum | Lightweight, corrosion-resistant | Aircraft, packaging, construction |

| Copper | Excellent conductivity | Electrical wiring, plumbing |

| Brass | Malleable, attractive finish | Fittings, musical instruments |

| Zinc | Corrosion-resistant | Galvanizing steel |

| Titanium | High strength-to-weight ratio | Medical implants, aerospace |

3. Key Differences Between Ferrous and Non-Ferrous Metals

| Feature | Ferrous Metals | Non-Ferrous Metals |

|---|---|---|

| Contains Iron | Yes | No |

| Magnetic | Usually | Rarely |

| Corrosion Resistance | Low (unless alloyed) | High |

| Weight | Heavier | Lighter |

| Common Use | Structural, industrial | Electrical, decorative, corrosion-resistant parts |

4. Applications in Industry

- Construction: Ferrous metals like steel and cast iron dominate in building frameworks and heavy-duty structures.

- Electrical and Plumbing: Copper and brass are standard in non-ferrous applications due to their conductivity and corrosion resistance.

- Automotive: Both types are used—steel for body parts and aluminum for reducing vehicle weight.

- Aerospace: Titanium and aluminum are crucial for weight-sensitive components.

5. Environmental Impact and Recycling

Both ferrous and non-ferrous metals are recyclable, but non-ferrous metals hold higher value in the scrap industry due to their scarcity and wide usability. Recycling contributes significantly to reducing energy use and mining waste.

6. Choosing the Right Metal for Your Application

When selecting a metal, consider:

- Mechanical Strength

- Corrosion Resistance

- Weight Requirements

- Conductivity

- Magnetic Needs

- Budget

Each industry has its specific standards, so consulting material engineers or suppliers ensures optimal selection.

Conclusion

Whether you’re in the construction, manufacturing, or electronics industry, knowing the difference between ferrous and non-ferrous metals is essential. Ferrous metals offer strength and magnetic properties, while non-ferrous metals provide corrosion resistance and lightness.

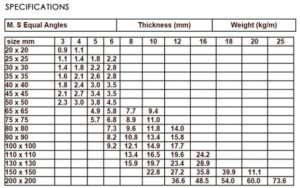

For more on metal categories and applications, explore our guide on Stainless Steel Pipe Fittings or check out the MS Angle Weight Chart for structural steel data.

FAQs

Q1: Is stainless steel a ferrous metal?

Yes, stainless steel is a type of ferrous metal because it contains iron, but it also includes chromium which resists corrosion.

Q2: Why are non-ferrous metals more expensive?

Non-ferrous metals are generally rarer, harder to extract, and have specialized applications, making them costlier.

Q3: Can ferrous metals be recycled?

Yes, ferrous metals are widely recycled and used in various industrial processes.

Q4: Which is better—ferrous or non-ferrous metal?

It depends on the application. For strength and structural uses, ferrous metals are ideal. For corrosion resistance or lightweight needs, non-ferrous metals are better.