In high-purity piping systems—especially in dairy, food, beverage, and pharmaceutical industries—every fitting matters. Two of the most widely used elbow types are the street elbow and the 90-degree elbow. While both are used to change flow direction, their construction, connection types, and use cases vary significantly.

Understanding these differences helps engineers, maintenance teams, and system designers make informed decisions for smooth, leak-free, and hygienic process flows.

What is a 90-Degree Elbow?

A 90-degree elbow is a standard pipe fitting used to create a sharp right-angle turn in a piping system. Both ends are typically female—designed to receive male-ended pipes or tubes.

Key Features:

Connects two pipes at a 90° angle

Common in dairy, pharma, and food-grade piping layouts

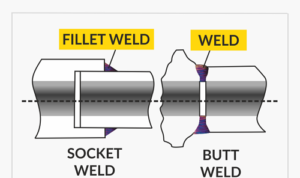

Available in socket weld, butt weld, and tri-clamp end types

Compatible with high-polish, hygienic Stainless Steel 316L Flanges for CIP/SIP systems

What is a Street Elbow?

A street elbow performs the same directional change but with a different connection style: one end is male, the other female. This allows the street elbow to directly join another fitting without a short pipe (nipple) between them.

Key Features:

One male and one female end

Reduces the number of joints in tight piping spaces

Ideal for compact systems and skid-mounted equipment

Commonly used with ASTM A269 Tubes and other sanitary components

Street Elbow vs. 90-Degree Elbow: Comparison Table

| Feature | 90-Degree Elbow | Street Elbow |

|---|---|---|

| Connection Type | Female–Female | Male–Female |

| Space Efficiency | Requires more room and fittings | Compact; eliminates need for nipple |

| Ideal Use | General process lines | Tight or modular installations |

| Hygiene Consideration | High if welds and joints are minimal | Fewer joints; easier to sanitize |

| Typical Applications | Long piping runs | Mobile units, CIP loops, short runs |

| Installation Time | Slower due to added connection | Faster and more direct assembly |

| Use With Sanitary Flanges? | Yes, with all flange types | Yes, especially when paired with Stainless Steel Flanges |

Which One Should You Use?

Choose a 90-Degree Elbow if:

Your system has space for additional fittings

You require symmetrical connections

You are using traditional welding or tri-clamp assembly

Choose a Street Elbow if:

Space is limited or layout is compact

You want to reduce the number of fittings

You are integrating into pre-assembled skid systems

Both options can be fabricated in 316/316L stainless steel for enhanced corrosion resistance and compliance with sanitary standards.

Use in Dairy and Pharmaceutical Applications

Mahadev Dairy Pharma provides sanitary elbows that comply with ASME BPE, 3A, and ISO standards. Whether you’re designing a pasteurization unit or a CIP return line, both elbow types can be manufactured with polished surfaces (Ra ≤ 0.4 µm) and are compatible with:

Final Thoughts

Both street elbows and 90-degree elbows play critical roles in hygienic and industrial piping. Your choice depends on system layout, space constraints, and process hygiene requirements. For precise, sanitary-grade elbows manufactured in compliance with industry norms, Mahadev Dairy Pharma offers a comprehensive range of stainless steel fittings.