In today’s hygiene-conscious industries, from food and beverage to pharmaceuticals and cosmetics, sanitary pipe fittings and stainless steel flanges and Sanitary Tube Fittings are essential components of clean, reliable fluid systems. These fittings are specifically engineered to meet strict standards for cleanliness, safety, and durability. In this comprehensive guide, we will cover everything you need to know about sanitary pipe fittings, including types, materials, standards, applications, pricing, and best practices.

What Are Sanitary Pipe Fittings?

Sanitary pipe fittings are specialized connectors used in fluid transfer systems where cleanliness is a top priority. These fittings ensure the safe transport of liquids and gases without contamination. They are usually made from 304 or 316L stainless steel, offering corrosion resistance and easy cleanability.

They feature smooth interiors, minimal dead space, and often have polished surfaces to reduce the risk of bacterial growth. These fittings support CIP (Clean-In-Place) and SIP (Sterilize-In-Place) processes, which are vital in sterile environments.

Why Are Sanitary Pipe Fittings Important?

In industries where contamination can lead to product failure or health risks, sanitary fittings ensure:

- Hygienic fluid transport

- Leak-free connections

- Compliance with FDA, 3A, and ASME BPE standards

- Resistance to corrosion, pressure, and temperature extremes

Materials Used in Sanitary Pipe Fittings

| Material | Characteristics | Applications |

| 304 Stainless Steel | Economical, corrosion-resistant | General food-grade environments |

| 316L Stainless Steel | Superior corrosion resistance, durable | Pharma, chemicals, high-purity use |

| PTFE, EPDM, Silicone | Gasket materials for secure, hygienic seals | Used with fittings for tight seals |

Types of Sanitary Pipe Fittings

Sanitary fittings come in a variety of shapes and functions. Here are the most common types:

- Elbows – Change direction of flow, typically 45° or 90° angles

- Tees – Split flow into two directions

- Reducers – Connect pipes of different diameters

- Ferrules – Provide a connection point for welding or clamp fittings

- Clamps – Secure tri-clamp fittings together

- Adapters – Transition between connection types (e.g., threaded to clamp)

Each fitting is designed to maintain hygienic conditions while supporting system efficiency and durability.

Connection Methods

There are several connection methods used for sanitary pipe fittings:

- Tri-Clamp (Tri-Clover): Quick, secure, and easy to clean. Most common in food and pharma.

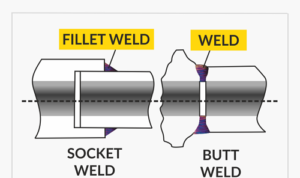

- Welded Ends: Permanent, leak-proof solution. Common in fixed systems.

- Threaded Fittings: Less common in sanitary applications due to potential contamination.

- SMS/DIN/RJT Unions: Standardized European connections used widely in breweries and dairies.

Each method offers a balance of cleanability, maintenance, and operational flexibility.

Applications of Sanitary Pipe Fittings

Sanitary pipe fittings are vital in industries that require the highest levels of hygiene:

- Food & Beverage: For safe transport of milk, beer, juices, and syrups

- Pharmaceutical: In cleanrooms and manufacturing of medicines

- Cosmetic Industry: Ensuring sterile production of lotions and creams

- Dairy & Brewing: Reliable flow of perishable liquids

Sanitary fittings are used in conjunction with clean-in-place (CIP) systems for operational efficiency.

Industry Standards and Certifications

To ensure quality and safety, sanitary fittings adhere to industry standards such as:

- 3A Sanitary Standards: For dairy and food equipment

- ASME BPE (BioProcessing Equipment): For pharmaceutical and bioprocessing systems

- FDA Compliance: For contact with consumables

- ISO 2852 / DIN / SMS: For international compatibility

Products meeting these standards undergo rigorous testing for material traceability, surface finish, and design.

Best Practices for Maintenance

Regular maintenance ensures the longevity and hygiene of sanitary fittings:

- Inspect seals and gaskets regularly for wear

- Clean with appropriate agents compatible with stainless steel

- Avoid abrasive tools during cleaning to preserve polish

- Schedule CIP cycles based on usage and material sensitivity

Maintaining sanitary pipe fittings reduces the risk of contamination and extends system life.

How to Select the Right Sanitary Fittings

When choosing sanitary fittings, consider:

- Material Compatibility: Match to your product (acidic, neutral, etc.)

- Connection Type: Choose based on maintenance needs and pressure ratings

- Certification Needs: Ensure compliance with 3A, ASME, FDA

- Application Specifics: For high-pressure systems, welded fittings may be best

Working with an experienced supplier ensures the best results for your specific system.

Indian Price Table for Sanitary Pipe Fittings (2025 Estimate)

| Fitting Type | Size Range | Average Price (INR/Unit) |

| Tri-Clamp Fittings | 1″ – 4″ | ₹150 – ₹600 |

| Sanitary Elbows | 1″ – 4″ | ₹120 – ₹500 |

| Tees & Reducers | 1″ – 4″ | ₹180 – ₹650 |

| Ferrules & Clamps | 1″ – 4″ | ₹100 – ₹350 |

| SMS/DIN/RJT Unions | 1″ – 4″ | ₹200 – ₹800 |

Note: Prices vary based on material (304 vs 316L), finish, and brand.

Material Comparison Table: 304 vs 316L Stainless Steel

| Property | 304 Stainless Steel | 316L Stainless Steel |

| Corrosion Resistance | Moderate | High |

| Cost | Lower | Higher |

| Applications | Food, water | Pharma, chemicals |

| Weldability | Good | Excellent |

| Chemical Composition | Cr, Ni | Cr, Ni, Mo |

Benefits of Using High-Quality Sanitary Pipe Fittings

Investing in high-quality sanitary pipe fittings provides long-term value:

- Reduced maintenance costs due to superior durability

- Fewer system failures with high-grade stainless steel and seals

- Better hygiene compliance with mirror-finish and anti-bacterial designs

- Improved efficiency through precision manufacturing and reliable connections

Reliable fittings reduce downtime and help ensure product integrity in sensitive environments.

Conclusion

Sanitary pipe fittings play a critical role in industries that depend on hygiene and system reliability. By understanding their types, materials, standards, and pricing, businesses can make informed decisions that ensure safety, efficiency, and compliance.

Whether you’re sourcing for a dairy plant, a pharmaceutical cleanroom, or a food-processing line, selecting the right fittings is crucial. Always choose certified, high-quality components from trusted suppliers.