Difference Between Alloy Steel and Carbon Steel: Full Guide for Engineers and Buyers

Steel is the backbone of modern infrastructure. From skyscrapers to pipelines, automotive frames to surgical tools, steel in its many forms shapes industries across the globe. Among the most commonly used categories are carbon steel and alloy steel. While they may look similar, their composition, performance, and applications are quite different.

In this article, we’ll break down the core differences between alloy steel and carbon steel, helping you understand which type best suits your project.

What Is Carbon Steel?

Carbon steel is steel that contains carbon as the main alloying element, with very little or no other significant alloying elements. Its properties are primarily defined by the amount of carbon in the steel.

Composition:

- Iron

- Carbon (up to 2.1%)

- Small amounts of manganese, silicon, and copper

Types of Carbon Steel:

- Low Carbon Steel (Mild Steel) – 0.05% to 0.25% carbon

- Medium Carbon Steel – 0.25% to 0.60% carbon

- High Carbon Steel – 0.60% to 1.5% carbon

Characteristics:

- Good tensile strength

- High hardness with higher carbon content

- Poor corrosion resistance

- Cost-effective

- Easily machinable and weldable (especially low carbon)

Common Applications:

- Pipes and tubes

- Structural steel

- Automotive components

- Bolts and fasteners

- Machine parts

What Is Alloy Steel?

Alloy steel is steel that is alloyed with other elements in addition to carbon. These elements are added in specific amounts to enhance certain properties such as strength, corrosion resistance, or hardness.

Common Alloying Elements:

- Chromium

- Nickel

- Molybdenum

- Vanadium

- Silicon

- Manganese

Types of Alloy Steel:

- Low Alloy Steel – Contains less than 5% of alloying elements

- High Alloy Steel – Contains more than 5% alloying elements (e.g., stainless steel)

Characteristics:

- High tensile and yield strength

- Superior corrosion resistance (especially when chromium is added)

- Improved wear resistance

- High-temperature tolerance

- Often more expensive than carbon steel

Common Applications:

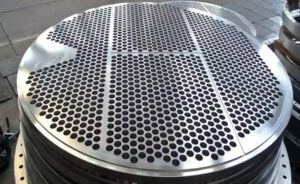

- Pressure vessels

- Power plants and boilers

- Gears and crankshafts

- Aerospace and automotive components

- Oil and gas pipelines

Key Differences Between Alloy Steel and Carbon Steel

| Feature | Carbon Steel | Alloy Steel |

|---|---|---|

| Main Elements | Iron + Carbon | Iron + Carbon + Other Alloys |

| Strength | Good (varies with carbon %) | Higher, customizable |

| Corrosion Resistance | Low | High (especially with chromium/nickel) |

| Toughness | Lower toughness at high carbon levels | Higher toughness and flexibility |

| Heat Resistance | Moderate | Excellent |

| Cost | Lower | Higher (due to added alloys) |

| Weldability | Easy (especially mild steel) | May require special procedures |

| Machinability | Good for low/medium carbon steel | Varies by alloy composition |

| Common Use Cases | Pipes, rebar, structural parts | Aerospace, chemical plants, high-pressure lines |

How to Choose Between Alloy Steel and Carbon Steel

The right choice depends on your application needs:

- Choose carbon steel if you need an affordable material with decent strength for low-stress applications (e.g., construction, piping).

- Choose alloy steel if your application involves high pressure, temperature, or corrosion (e.g., boilers, chemical plants, oil rigs).

For example:

- A mild steel sanitary tube may be suitable for water piping.

- A chromium-molybdenum alloy tube is better for high-temperature boilers.

Material Grades Example

| Grade | Type | Description |

|---|---|---|

| ASTM A106 | Carbon Steel | Seamless pressure pipe |

| ASTM A105 | Carbon Steel | Forged piping components |

| ASTM A335 P11 | Alloy Steel | Chrome-moly pipe for high-temperature service |

| ASTM A182 F22 | Alloy Steel | Forged fittings for pressure systems |

Conclusion

Both carbon steel and alloy steel have their strengths, and choosing the right one depends on the demands of your application. If you’re looking for cost-effective solutions for standard strength requirements, carbon steel is a great option. But when your project requires high durability, heat resistance, or protection against corrosion, alloy steel is the superior choice.

At Mahadev Dairy Pharma Fittings, we supply a wide range of carbon and alloy steel fittings, tubes, and components designed for industrial, dairy, and pharmaceutical systems. Reach out to our experts to choose the right material for your application.